In logistics, every second counts. Each delay in order picking, every mis-scanned pallet, or misplaced item has a cost that ripples across operations. As supply chains become increasingly time-sensitive, warehouse automation has become an essential strategy for sustaining speed, accuracy, and profitability.

Across Dubai and other logistics hubs, companies are under constant pressure to deliver more in less time—without expanding their workforce or warehouse footprint. This is where automation enters the picture. It’s not simply about installing robots or conveyor belts; it’s about designing a facility and process ecosystem that works with data, machinery, and people in perfect sync.

For businesses planning new warehouse projects or modernising existing ones, the question is clear: how can you automate warehouse processes efficiently, and what will it cost? Let’s explore how automation builds smarter, leaner operations and how to plan an investment that pays off.

Table of Contents

The Growing Urgency for Warehouse Automation

A logistics landscape built on speed

E-commerce growth and global trade expansion have intensified the demand for faster and more precise fulfilment. Customers expect next-day or same-day delivery, while production schedules and stock levels fluctuate unpredictably. In this environment, manual workflows struggle to keep pace.

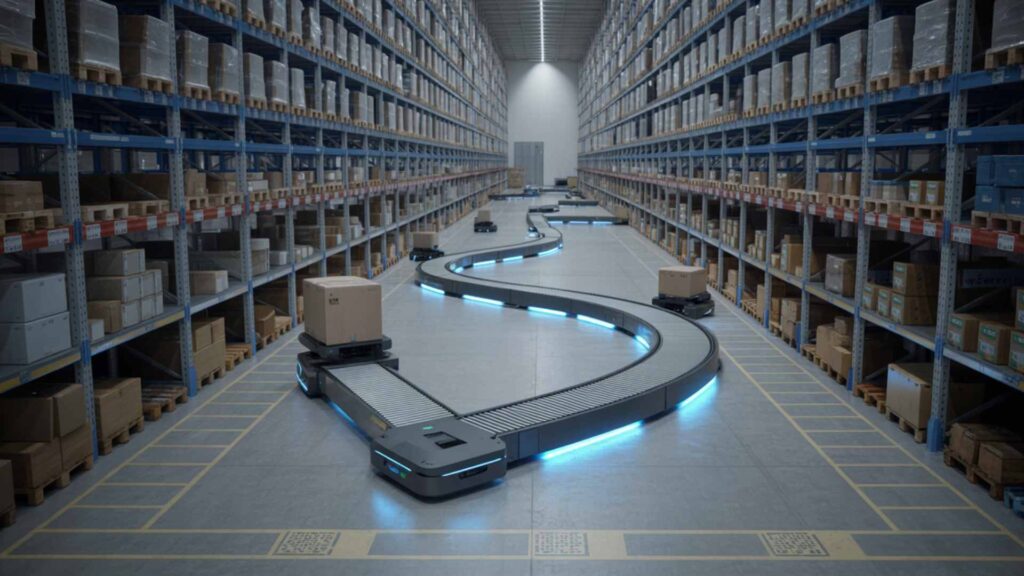

Automated systems can handle high-volume operations continuously, without fatigue or inconsistency. They can sort, pick, and move products at speeds that would be impossible to achieve manually. More importantly, they generate operational data that helps managers forecast demand, optimise routes, and maintain stock visibility in real time.

Labour and operational challenges

Warehousing has long depended on manual labour for repetitive tasks such as picking, sorting, and packaging. Labour shortages, training costs, and turnover have increased operational instability. Automation doesn’t eliminate human roles—it redefines them toward supervision, analytics, and process optimisation.

With technologies like autonomous mobile robots (AMRs), automated storage and retrieval systems (AS/RS), and warehouse management systems (WMS), employees can focus on exception handling and performance monitoring instead of repetitive movement. The result is a more balanced and efficient workforce.

Consistency and compliance

Automated systems improve consistency by standardizing processes and maintaining traceability. In industries like pharmaceuticals or food logistics, where every batch must meet strict documentation standards, automation ensures compliance through real-time monitoring and digital record-keeping.

Core Elements of Warehouse Process Automation

Receiving and Put-Away

The automation journey begins at the receiving dock. Barcode or RFID-enabled systems instantly register inbound goods, update inventory levels, and direct items to designated locations. Automated guided vehicles (AGVs) or conveyors then transport pallets or cartons to assigned racks with minimal manual intervention.

This stage eliminates the bottlenecks that typically occur during inbound checks and inventory recording. Each item is tracked from the moment it enters the facility, building a digital foundation for the entire supply chain.

Storage and Retrieval

Automated Storage and Retrieval Systems (AS/RS) represent the core of an efficient automated warehouse. These systems use shuttles, cranes, or robotic lifts to store and retrieve goods within dense racking structures. They maximise vertical space and improve space utilisation by up to 40%.

In a high-volume operation, this level of precision significantly reduces travel time for goods and enhances throughput. The system communicates continuously with the WMS to identify the optimal storage location based on product type, turnover frequency, or temperature requirements.

Order Picking and Sorting

Order picking consumes a major share of warehouse time and cost. Automation technologies such as pick-to-light systems, robotic picking arms, and goods-to-person systems reduce manual walking and handling. Items are brought directly to the operator’s workstation, cutting travel distances and improving picking accuracy.

Automated sortation systems then classify orders according to size, destination, or priority, ensuring every order moves seamlessly toward packing and dispatch.

Packing and Dispatch

Automated packing lines use scanners, label applicators, and weighing systems to prepare goods for shipment. Integrated WMS platforms coordinate the sequence, assign carrier slots, and record real-time dispatch data. By the time goods leave the dock, every movement is already logged, creating complete traceability.

Inventory Management and Analytics

A fully automated warehouse runs on data. The WMS gathers real-time input from scanners, RFID readers, and robotic sensors. Managers can monitor inventory levels, identify slow-moving stock, and plan replenishments precisely. With advanced analytics and machine learning, the system can even predict demand spikes or detect patterns that indicate inefficiency.

Building an Automation-Ready Facility

Automation begins with infrastructure. The physical warehouse must be designed to accommodate equipment, data connectivity, and traffic flows. Retrofitting an old facility for automation can be expensive, but smart planning during construction can drastically reduce future costs.

Structural Design

The warehouse structure must support high-load racking systems, automated cranes, and mezzanine platforms. The floor must have adequate load capacity and precision levelling for robotic movement. Ceiling height and column spacing should allow for vertical automation and unimpeded robotic paths.

Utilities and Connectivity

Power distribution, data cabling, and Wi-Fi connectivity are critical. Automation systems rely on uninterrupted connectivity between robots, sensors, and management software. Energy efficiency should also be considered; systems like regenerative drives and smart lighting reduce ongoing utility costs.

Safety and Maintenance Provisions

Safety barriers, emergency pathways, and maintenance zones must be incorporated into the layout. Regular maintenance access for conveyors, lifts, and robotic systems ensures uptime. Predictive maintenance software can also track equipment health and schedule service proactively.

At Dura Altaj Contracting, these considerations form the core of automation-ready design. Our approach integrates structural engineering with process planning, ensuring the facility supports both current and future automation needs.

The Cost of Automating a Warehouse

The cost of automation varies widely depending on facility size, technology level, and integration scope. Yet, understanding the general cost structure helps businesses plan effectively.

Initial Investment

For a mid-sized facility, partial automation, such as conveyor networks, barcode systems, and WMS integration, may cost between USD 300,000 and 1 million.

For larger, highly automated setups with AS/RS cranes, robotics, and advanced data systems, investments can range from USD 1 million to 5 million or more.

Key factors affecting cost include:

- Warehouse floor area and height

- Degree of automation (basic, hybrid, or full robotic)

- Integration with ERP or WMS platforms

- Software licensing and IT infrastructure

- Retrofitting complexity if upgrading an old facility

- Vendor selection and import costs for machinery

Operational and Maintenance Costs

Beyond capital expenditure, there are recurring costs:

- System maintenance and servicing contracts

- Software updates and cybersecurity

- Energy consumption

- Operator and technician training

- Spare-part management and warranty extensions

However, these are balanced by ongoing savings in labour, reduced error rates, improved space use, and faster order fulfilment.

Return on Investment (ROI)

Calculating ROI involves comparing your total investment with the annual savings generated through automation.

For example:

- A warehouse that spends USD 200,000 annually on manual labour may reduce that by 30–40% through automation.

- If automation reduces errors by 50%, returns and re-handling costs also drop significantly.

- Faster throughput means higher sales capacity without expanding space.

Many operations report ROI within three to five years, depending on project scale and execution discipline.

Step-by-Step Approach to Warehouse Automation

Step 1: Process Assessment and Data Collection

Begin by mapping current workflows. Identify bottlenecks, redundant movements, and areas of excessive manual handling. Gather data on order volumes, travel distances, and error frequency. This baseline helps quantify improvement potential.

Step 2: Define Automation Goals

Determine what the business needs to achieve higher throughput, fewer errors, space optimisation, or labour efficiency. Clear goals shape the choice of technology and investment level.

Step 3: Select Technologies and Partners

Choose technologies aligned to your goals. For example, AS/RS systems for dense storage, AMRs for flexible movement, or vision-guided robots for picking. Select partners with proven integration expertise.

Step 4: Facility Design and Infrastructure Planning

Design the warehouse layout around process flow. Plan racking systems, aisles, and equipment placement for smooth movement. Ensure utilities, connectivity, and safety systems are built to specification.

Step 5: Pilot Implementation

Start with a controlled pilot, perhaps automating one zone or process such as order picking. Use this phase to fine-tune integration, train staff, and evaluate real-time performance.

Step 6: Scale Gradually

Expand automation in stages based on pilot results. Continuous learning and refinement prevent disruptions during scale-up.

Step 7: Train and Empower Staff

Employees must adapt to new workflows. Training builds confidence and ensures optimal system usage. Skilled operators and technicians are vital for long-term reliability.

Common Mistakes to Avoid

- Ignoring facility readiness: Many companies focus on buying automation equipment before verifying that their facility structure, flooring, or utilities can support it.

- Underestimating data integration: Software alignment between WMS, ERP, and robotics is critical. Poor integration causes downtime and inaccurate reporting.

- Over-automation: Investing heavily in technology that exceeds operational needs increases payback time and complexity.

- Skipping maintenance planning: Without preventive maintenance, downtime and repair costs escalate quickly.

Future Trends in Warehouse Automation

The next wave of warehouse technology combines automation with artificial intelligence and data analytics. Predictive algorithms will dynamically adjust picking sequences and inventory placement based on demand trends.

Collaborative robots (cobots) will work alongside humans for flexible, safe operations. Digital twins will allow managers to simulate workflows before implementation, identifying bottlenecks virtually. Sustainability will also guide design, with energy-efficient drives, solar integration, and recyclable material use becoming common.

For construction and engineering partners like Dura Altaj, these trends highlight the need for adaptable, future-proof facilities that can host evolving technologies without reconstruction.

Dura Altaj Contracting’s Approach to Automation-Ready Warehouses

At Dura Altaj, automation readiness begins with design foresight. We engineer warehouse facilities that combine architectural efficiency with technology integration potential.

Our expertise covers:

- Structural Design: Floor load analysis, racking foundations, and mezzanine systems for heavy automation equipment.

- Layout Optimisation: Flow planning to support robotic traffic, conveyor lines, and ergonomic workstations.

- Utility Planning: Scalable power and network design for automation and data systems.

- Safety Engineering: Barrier systems, emergency access, and maintenance zoning.

- Turnkey Execution: Coordinated delivery of civil construction, interior works, and system fit-outs.

Each project is built to deliver longevity, operational agility, and readiness for the next stage of automation.

Building an Automation Strategy That Works

Warehouse automation is an evolving journey. A successful strategy balances infrastructure, process design, and workforce transformation. It begins with a clear understanding of operational challenges and ends with measurable performance gains.

Decision-makers should focus on:

- Strategic alignment – automation should support business goals, not drive them.

- Scalability – systems should grow with demand, not restrict it.

- Integration – software, hardware, and facility must operate as one unit.

- Sustainability – energy-efficient and low-maintenance systems ensure long-term value.

When automation aligns with design thinking and sound infrastructure, warehouses become high-performance ecosystems which is efficient, resilient, and ready for the future.

Conclusion: Building Smart, Future-Ready Warehouses with Durra Altaj

Warehouse automation has become an essential part of modern logistics. Every improvement in accuracy, speed, and space utilization depends on how well the facility is planned and constructed.

Durra Altaj Contracting designs warehouse spaces that support automation from the ground up. Every element, from floor design and loading capacity to workflow zoning and equipment placement, is engineered to ensure seamless operation of automated systems.

The investment in automation delivers measurable results through consistent productivity and reduced operational costs. A well-constructed facility enables automation to function at its best, maintaining high efficiency across every process.

Dubai’s logistics sector continues to expand, and automated warehouses are shaping its next phase of growth. Durra Altaj brings technical expertise, construction precision, and an understanding of modern warehouse requirements to help businesses achieve long-term operational excellence.

Smart warehouses stand on a foundation of quality construction and thoughtful planning. Durra Altaj Contracting builds that foundation with reliability and attention to every operational detail.

.