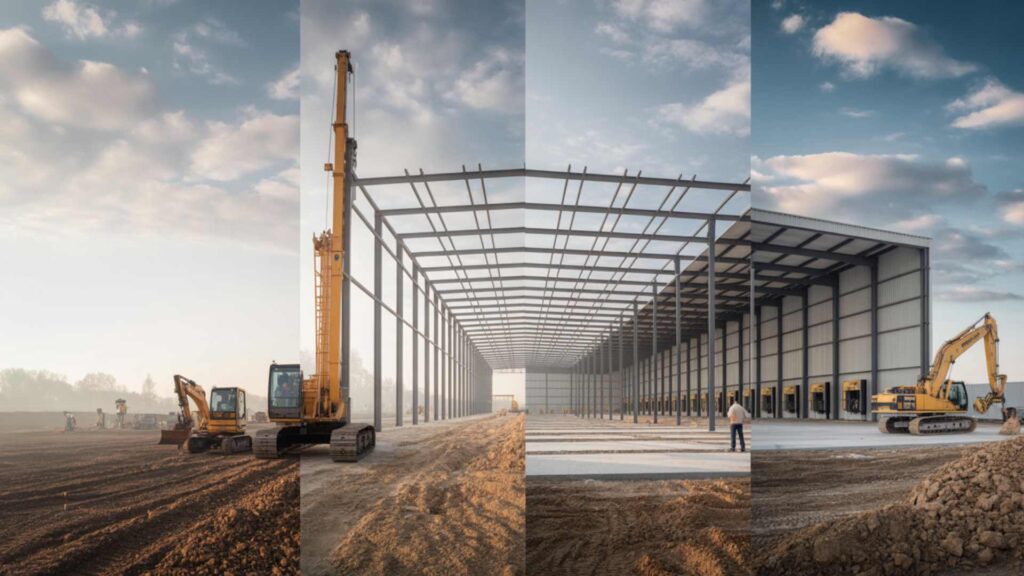

Behind every efficient supply chain is a well-built warehouse. These facilities don’t appear overnight; they evolve through a series of carefully managed steps that transform bare land into a logistics hub capable of handling thousands of goods daily.

In the UAE, warehouses play a central role in global trade, e-commerce growth, and industrial expansion. The region’s strategic location and rapid economic diversification have increased demand for modern storage and distribution centers. Constructing these warehouses requires precision, regulatory compliance, and a future-ready mindset.

This guide breaks down the 9 essential stages of warehouse construction, offering a detailed look at what happens at each step, the decisions that matter most, and how businesses can ensure a successful project.

Table of Contents

Stage 1: Planning, Needs Assessment & Site Selection

The planning stage of the warehouse sets the tone for the entire project. Skipping details here can lead to costly redesigns later.

Needs Assessment: Define warehouse purpose—bulk storage, e-commerce fulfillment, cold storage, or manufacturing support. Each requires a different layout, ceiling height, and loading system.

Scalability: Growth plan. UAE businesses often expand quickly due to trade opportunities. A design that allows extensions saves future investment.

Site Selection: Location is strategic. Sites near Jebel Ali Port, Dubai South, or Abu Dhabi’s industrial zones provide better connectivity. Soil stability and flood risk must also be evaluated.

Logistics Factors: Accessibility for heavy trucks, proximity to highways, and traffic conditions are crucial in ensuring smooth goods movement.

Feasibility & Risk Assessment: Conduct soil risk studies, evaluate demand forecasts, and prepare risk mitigation strategies.

👉 A carefully chosen site with clear operational goals ensures the warehouse adds value to the supply chain from day one.

Stage 2: Budgeting, Procurement & Regulatory Approvals

Construction budgets in the UAE must account for more than just materials and labor.

Cost Breakdown: Land, civil works, PEB structures, fit-outs, MEP systems, automation, and contingencies. A typical warehouse budget can vary from AED 800 to AED 1,500 per sqm depending on complexity.

Procurement Strategy: Select between design-build, turnkey, or phased contracting. Prequalify subcontractors with UAE warehousing experience.

Regulatory Approvals:

Zoning permissions to ensure land use aligns with warehouse functions.

Environmental permits to comply with sustainability laws.

Fire safety approvals under UAE Civil Defence requirements.

Municipal building permits for legal construction.

Delays in approvals are one of the most common reasons projects stall. Experienced contractors help fast-track documentation and compliance.

Stage 3: Design & Engineering

Warehouse design blends architecture with engineering science.

Layout Efficiency: Workflows must reduce handling time. For e-commerce hubs, designs often include automated sorting zones and conveyor systems.

Structural Design: Pre-Engineered Buildings (PEB) are favored in the UAE for faster construction and resilience in desert climates.

MEP Planning: Efficient HVAC reduces energy bills. Fire detection and sprinkler layouts must follow Dubai Civil Defence standards.

Safety & Compliance: OSHA standards and UAE-specific codes shape safe aisle widths, emergency exits, and load-bearing capacities.

Sustainability Integration: Early design should allow for solar panels, passive cooling, and energy modelling for long-term efficiency.

A well-engineered design not only meets today’s needs but also accommodates automation upgrades like robotics and AI-driven warehouse management.

Stage 4: Site Preparation & Foundation

Before steel frames rise, the land must be prepared to handle heavy loads.

Clearing & Grading: Removing debris, vegetation, or old structures.

Soil Testing: Conduct geotechnical studies to check bearing capacity. Weak soil may require piling or reinforcement.

Drainage Systems: In desert areas, sudden rainfall can flood poorly designed sites. Grading and stormwater management prevent downtime.

Foundation Laying: Reinforced concrete slabs are standard. For cold storage, insulated flooring with vapor barriers is essential.

Proper site preparation prevents structural cracks, uneven flooring, and costly repairs later.

Stage 5: Structural Framework & Exterior Build

This is where the warehouse visibly comes to life.

Steel Framework: PEB structures are fabricated off-site and assembled quickly.

Roofing & Cladding: Insulated sandwich panels are common in the UAE to combat high temperatures.

External Features: Roller shutters, loading bays, dock shelters, skylights, and ventilation systems.

Durability Considerations: Material choices must withstand dust, humidity, and heat.

At this stage, the skeleton of the warehouse is complete, providing shape and structure to the project.

Stage 6: MEP Installation, Fit-Out & Technology Provisioning

A warehouse becomes operational when its systems are integrated.

Mechanical Systems: HVAC, exhaust fans, and cooling systems for sensitive goods.

Electrical Systems: LED lighting, high-bay fixtures, backup generators, and smart meters.

Plumbing & Drainage: Water supply, restrooms, and floor drains for industrial washing.

Fire Safety: Sprinkler networks, smoke detectors, hydrants, and alarms per Civil Defence.

Interior Fit-Out: Mezzanine floors, racking, partitioned office spaces, signage, and flooring.

Technology Provisioning: Conduits and trunking for future automation, IoT sensors, and robotics.

This stage tailors the warehouse to specific business requirements, ensuring smooth operations once active.

Stage 7: Quality Inspection & Safety Compliance

Before commissioning, the warehouse undergoes rigorous inspections.

Structural Testing: Ensures load-bearing integrity.

Electrical & Fire Checks: Verifies compliance with UAE fire safety codes.

Workflow Validation: Confirms layout supports smooth movement of goods.

Final Adjustments: Contractors address punch-list issues like sealing gaps or aligning dock doors.

A warehouse that passes inspections provides peace of mind and operational readiness.

Stage 8: Commissioning, Handover & Staff Training

Once construction is complete, the facility is handed over for use.

System Commissioning: Final testing of HVAC, electrical, and fire systems.

Documentation & Warranties: Compliance papers, manuals, and guarantees are provided.

Staff Training: Employees are trained on equipment use, fire safety, and emergency protocols.

This ensures the transition from construction site to functioning warehouse is seamless.

Stage 9: Maintenance Planning, Monitoring & Future Upgrades

A warehouse is a long-term investment, and its performance depends on proactive care.

Maintenance Scheduling: Regular checks for roofing, flooring, HVAC, and fire systems.

Energy Optimization: Retrofitting with solar panels or energy-efficient HVAC reduces costs.

Automation Upgrades: Robotics, IoT sensors, and AI-driven WMS systems keep warehouses competitive.

Performance Monitoring: Post-occupancy evaluations track energy use, workflow efficiency, and worker feedback.

By planning ahead, businesses ensure warehouses continue to deliver value for decades.

Quick Checklist: 9 Stages of Warehouse Construction

Planning, Needs Assessment & Site Selection

Budgeting, Procurement & Regulatory Approvals

Design & Engineering

Site Preparation & Foundation

Structural Framework & Exterior Build

MEP Installation, Fit-Out & Technology Provisioning

Quality Inspection & Safety Compliance

Commissioning, Handover & Staff Training

Maintenance Planning, Monitoring & Future Upgrades

Conclusion

Constructing a warehouse is a structured journey. Each stage, from planning and site preparation to commissioning and maintenance, plays a vital role in shaping how efficiently the facility operates.

For businesses in the UAE, where logistics hubs must serve both local and international markets, working with experienced contractors like Durra Altaj ensures that every phase is executed with precision. The result is more than a building; it’s an asset that supports growth, efficiency, and long-term business success.

FAQs

1. How long does it take to build a warehouse in the UAE?

A medium-sized warehouse may take 6–12 months, while larger facilities with advanced features can extend beyond a year.

2. What is the average cost of warehouse construction in Dubai or Abu Dhabi?

Costs vary based on design and materials. On average, construction can range between AED 1,200 to AED 2,000 per sqm, with high-tech facilities costing more.

3. Do warehouses in the UAE require special permits?

Yes. Approvals are needed from municipal authorities, civil defence, environmental regulators, and sometimes free zone authorities.

4. Can I customize a warehouse design for future expansion?

Absolutely. Modular layouts allow businesses to add mezzanine floors or automation systems without major disruptions.

5. What type of roofing is best for warehouses in the UAE?

Steel roofing with proper insulation is common due to durability and heat resistance. Skylights or solar panels improve efficiency.

6. How important is flooring in a warehouse?

Very important. Industrial-grade concrete floors support heavy racking, forklifts, and machinery. Epoxy coatings enhance durability.

7. Should I consider automation during warehouse construction?

Yes. Planning early avoids costly retrofits. Many UAE warehouses integrate conveyors, ASRS, and IoT-based tracking.

8. Do free zones in the UAE offer warehouse construction opportunities?

Yes. JAFZA, KIZAD, and DIC provide land leasing and streamlined approvals for warehouses.

9. How can Durra Altaj help with my warehouse project?

Durra Altaj specializes in end-to-end industrial construction, covering design, civil works, steel structures, and finishing. With expertise in UAE regulations, we deliver cost-efficient and future-ready warehouses.